Our Technology

All of Moxie’s design, development, and production happens in-house: we’re not just a middle-man. Every stage of development is known and understood by every person involved in the project, resulting in a final product that is accurate and cohesive.

Most Internet-of-Things (IoT) products consist of five separate pieces: Printed Circuit Boards, Embedded Code, Enclosure & Hardware, Network Communication, and a User Interface. All of these components must merge together seamlessly or your product will struggle keep up with modern consumer expectations. Moxie provides all the pieces necessary to create a complete IoT system.

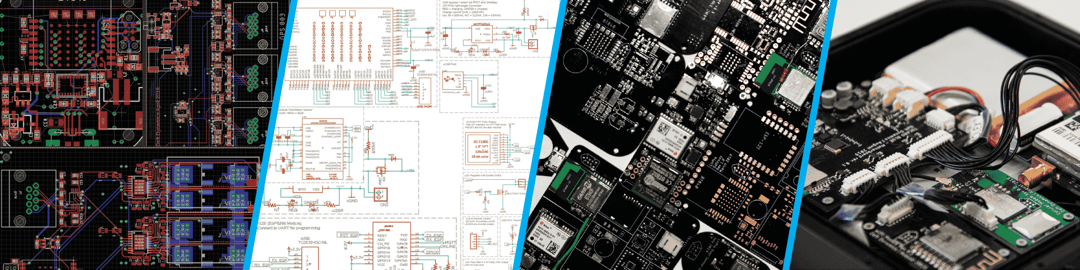

Printed Circuit Board (PCB)

The PCB is a critical part of creating electronics products. Even the simplest modern electronics contain dozens of individual parts which must be linked together electrically. Power sources, sensors, micro-computers, and customized electrical circuits all communicate and work together to produce useful outputs. The fiberglass PCB provides a platform to hold these parts and creates electrical connections between them. Electrical Engineers at Moxie have created a semi-automated system to build these circuits, and the PCB to hold them, quickly and accurately. Moxie has partners to create PCB prototypes and production, and in-house robotic SMT Pick-and-Place equipment that can place thousands of tiny components electronic components per hour.

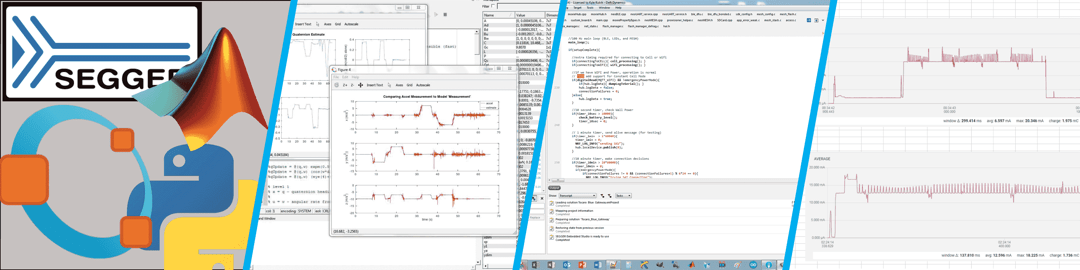

Embedded Code

Most PCB circuits are controlled by a micro-computer (also called a micro-controller or MCU) which is custom-programmed to perform the sensing and logic which performs specialized tasks. Moxie application engineers create customized code for each new PCB. The code will read sensors, calculate new information, and communicate with a human interface such as a phone app or the internet. This set of code is called ‘firmware’ since it is code (software) but usually is not updated after the host PCBs are tested and mass-produced. Moxie is constantly expanding our libraries with specialized math and drivers to connect sensors and actuators, so the tools are ready and tested when a new application requires them. Our flagship products are based on Nordic micro-controllers that natively support Bluetooth and can be expanded to connected to the best network based on your needs.

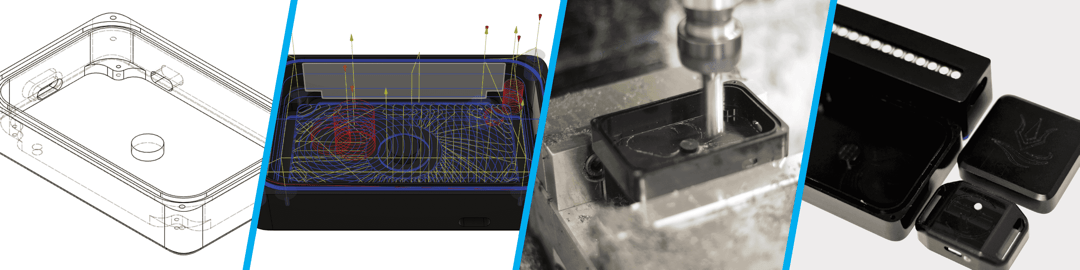

In-House Prototyping

An enclosure protects the PCB and creates the look and feel of an IoT product. Enclosures can range from simple ‘boxes’ with a few buttons or lights, to complex artistic designs, to durable industrial casings that are resistant to water, dust, and impact. While the PCB and Firmware create the embedded functionality of an IoT product, the way a user interacts with it will be based on the enclosure it is in. The PCB, Firmware, and Enclosure together comprise a complete IoT Device. Moxie uses in-house 3D printing and CNC milling equipment to create prototypes, and we have industry partners on-call for building hundreds or thousands of parts in production.

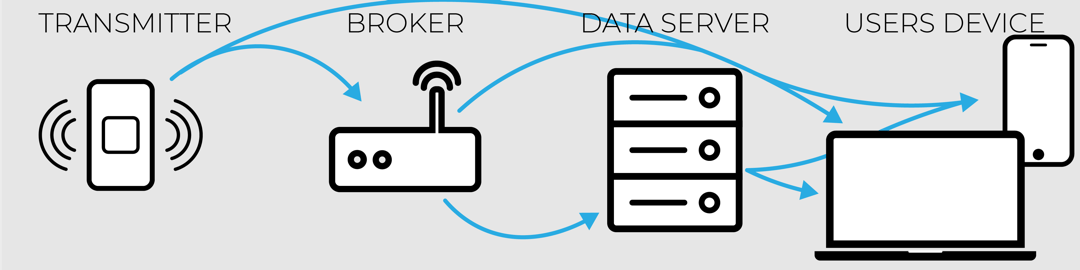

Network Communication

One major premise of IoT is that data will be available for viewing from anywhere, no matter where the IoT Device is located around the world. To get this data to the user reliably, devices will need to create or join a network. If a smartphone-user is nearby, Bluetooth Smart (BLE) is a safe, reliable, and efficient solution. For two devices to speak to each-other, Bluetooth MESH or wired connections are ideal. For applications where the user is not nearby, WIFI or Cellular (LTE CAT-M1) are used based on user need. WIFI is best for high data throughput, but is not reliable and is often subject to intervention by network administrators. Cellular is best for long range and reliable connections, but requires monthly subscription costs based on the amount of data transferred. IoT devices usually send data to our fast ‘real-time’ MQTT server, from which it can be sent directly to a phone for display, or into a database for long-term storage.

User Interface

Almost every Internet-of-Things (IoT) user carries a smartphone, with a powerful computer and brilliant display, in their pocket. Modern IoT Devices take advantage of this by building their interface in a smartphone application rather than adding costly displays onboard the IoT Device. Many companies can develop applications that display information or events and act similar

to websites, but Moxie has specialized in connecting the smartphone interface to physical hardware like IoT devices. Whether you need an interface to collect and supervise sensor data, or to control an industrial process, Moxie will tailor a user interface and experience to you and your customers’ needs. We leverage the power of Flutter to build apps that work seamlessly across iOS and ANDROID, and use the latest security tools to keep your data safe.