MoxieWORLD is a comprehensive asset tracking and productivity solution for industrial applications – basically it’s a GPS that works indoors. The information this system generates is able to increase workplace productivity, efficiency, and safety within days of setup. The MoxieWORLD app recreates a 3D digital twin of any facility and allows you to monitor real-time and historic metrics through powerful and intuitive visualization. This project demonstrates the full suite of Moxie capability: electronic hardware, IoT network, and app design.

Hardware

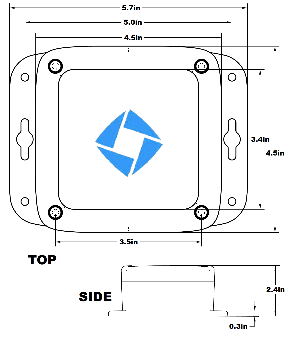

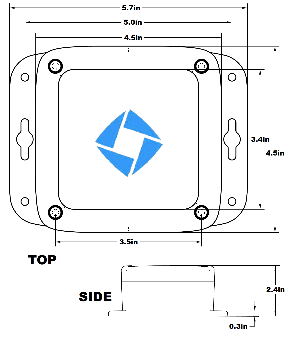

The foundation of moxieWORLD asset tracking is the moxieTAG, which is attached to your mobile equipment and tracks its indoor location to within 10 inches (25 cm) along with performance data like temperature and power consumption. Traditional precision-asset-tracking uses GPS, which only works with a clear view of the sky. This system is able to triangulate its indoor position based on reference stations, the moxieANCHORs, which are mounted at convenient locations on the walls/columns near the workspace (approximately every 50 meters). The embedded system includes a UWB positioning algorithm, circuit board and firmware to implement that algorithm, Bluetooth communication for setup in an app, WIFI for streaming information to the internet, and a waterproof enclosure designs. A portfolio of ‘Plus One’ sensors can be added to any moxieTAG and provide additional data such as machine power consumption and environmental conditions.

| UWB System |

nRF52840 Cortex M4F (Bluetooth MCU) UWB TWR Transceiver Up to 155 tags per network (10 second update) |

| Network Options |

Bluetooth 4 for direcet connection to smartphone app 2.4GHz WiFi |

| Physical Specs |

Power Source: 100-277 VAC | 5-24 VDC | 12-24 VAC Polycarbonate Enclosure, IP 67, UL 508A, 80°C |

| ‘Plus One’ Options |

Encoder input (crane hoist, CNC travel, etc.) AC current clamp (non-invasive 3-phase monitor) |

IOT Network

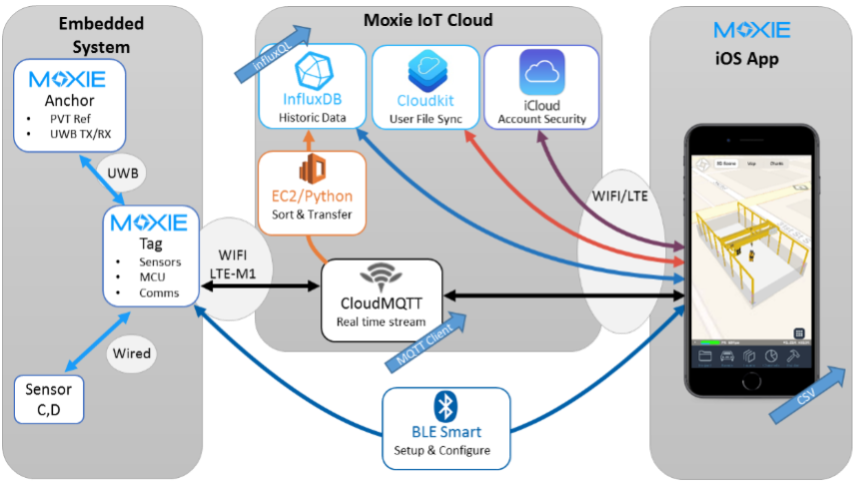

The heart of moxieWORLD is the IoT network which efficiently delivers data from the moxieTAG to the end user. The data is handled by two parallel networks, a real-time stream and a historic database, each valuable for different end-use cases.

IoT data for asset tracking and monitoring is a small but continuous stream of sensor data. This lightweight stream is handled elegantly by a MQTT broker which allows thousands of moxieTAGs to securely upload their data to the cloud at low data costs. For real-time monitoring, smartphones and web-apps can subscribe to the stream of information for each tag and receive it in less than a second – this is how the moxieWORLD app is able to display a digital twin in real-time. Moxie IoT has developed a method for packing IoT data in an efficient way, then transmitting it through a single broker but secured in a way that allows only the owner of each tag to see its data.

All IoT data that flows through the broker is parsed and stored in a Time-series database, providing two years of historical records, timestamped with resolution down to the second. The historic data is perfect for preventative maintenance or integration with the client’s existing analytics tools like PowerBI.

iOS Application

The best way to experience MoxieWORLD real-time tracking capability is in a digital-twin of the facility. Moxie IoT built an iOS app that is optimized for iPad and can be used to install and configure your moxieANCHORs and moxieTAGs, create a digital twin of your facilities with high-quality graphics, and review historic data. The iOS app connects to nearby moxieTAGs using Bluetooth, allowing clients to configure settings, monitor sensor data (like 3-phase power cycles), and to automatically ‘survey’ the locations of your moxieANCHORs. Drag and drop functionality allows anyone to quickly create an outline of your facilities, to create virtual keep-out or safety zones, and to associate tags with high-quality 3D models of cranes, forklifts, and CNC mills. Historic performance is displayed alongside real-time information so clients have a complete picture of productivity, for the facility as a whole or down to each individual machine.